The MIMO Approach to Research

Research Collaboration Program

The MIMO Research Collaboration Program creates new knowledge to solve industry problems.

Industrial Implementation Study

Most impactful use cases and implementation best practice.

Historical Analysis

Analysis of machine learning in 1300 manufacturing internships over 30 years – problem solution prevalence.

Intelligent Manufacturing Systems

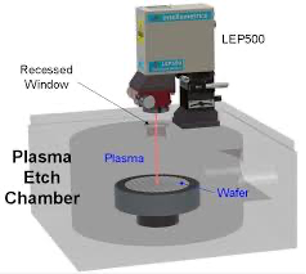

Example Project: Semiconductor Production

Objective:

- Develop robust fault detection methodology for ion implantation and plasma etching processes

Phases:

- Demonstrate fault detection on ion implantation and plasma etching data

- Improve methodology to adapt to changing process dynamics (i.e. concept drift)

- Identify technique to preemptively raise alerts before a fault occurs and bad product is manufactured

- Determine the methodology to transfer technique to new recipes and tools with limited historical data

Example Project: Automobile Engine – Virtual Quality Gate

Objective:

- Develop a “Virtual Quality Gate” predictive model with existing data (incoming component data, assembly process data and quality confirmation data) to identify units that have a high potential to fail

Execution:

- 2 PhDs – 2 Years

- Combine formally siloed data from Process / Test / Quality Engineering and Supply Chain

- Thousands of variables analyzed: time-series, categorical, spatial

- Real-time “Go, No Go” Decisions

- Employee Training in Machine Intelligence Methods

- Organizational Transformation – Key Requirement

Intelligent Supply Chain

Example Project: Inventory positioning for omni-channel performance

Objective:

- Develop a new replenishment policy and identify SKUs in need of updated warehouse and store handling characteristics to enable a leaner last mile supply to stores.

Phases:

- SKU warehouse and store handling characteristics, store shelf space and replenishment policy alignment analysis.

- Replenishment policy update leveraging historic actuals identified through simulation and implemented in pilot.

- Policy update validation: SKU with forecast inaccuracies identified and correction method proposed for roll-out.

- Simulation tool to compute tradeoffs in different policies at different handling characteristics.

- Leverage deployment of automation in warehouses

Example Project: Assortment Optimization for Beverage Distributor

Objective:

- Recommend customized assortments for 400k stores, with 1000s of SKUs available

Phases:

- Analyze historical demand data that is censored by current assortment choices

- Fit choice model and impute demand across all store-SKU combinations, based on historical data and product, store features similarities

- Optimize assortments to increase market share or revenues

- Analyze demand for potential new product introductions based on product feature similarities

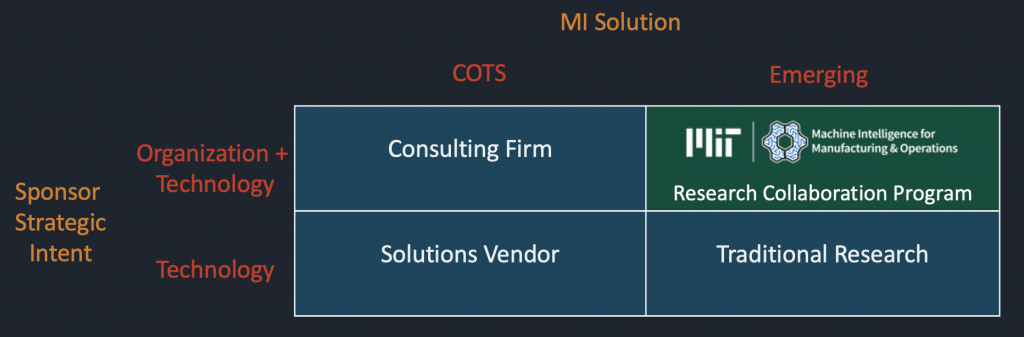

Research Collaboration Program

MIT MIMO developed the Research Collaboration Program for companies who want improve their processes via machine intelligence but have complex problems that COTS solutions cannot address.

Technology

- Applied Research – Apply the best solution rather than the newest

- Implementation Focus – Create a working prototype

- Impactful Business Outcome – Focus high value projects

- Field-Based – Solve real problems with hands on approach

- Long-term mindset – Address issues of process drift and technology transfer

Organization

- Create Data Science Team

- PhD, Faculty – Core research

- Sponsor Company – project lead, production engineers, data engineer, data scientist

- Optional LGO Internship integration – Implementation Issues, Organizational Integration

- Build Internal Skills – Educate local team on the tools and techniques used

- Implement Structured Process – Identify key tasks, questions and milestones

- Broaden Enterprise Awareness – Optional classes and case studies to extend solution across enterprise

MIMO and McKinsey & Co. collaborative study of AI in manufacturing and operations

The MIT MIMO and McKinsey & Co. collaborative study of artificial intelligence (AI) in manufacturing and operations now live in the current edition of the Harvard Business Review. This first-of-its-kind study is a comprehensive undertaking to identify how manufacturing and operations leaders create the right organizational capabilities and prioritize the use cases with the largest KPI improvements.